In the world of hydraulic systems, Linde hydraulic pumps have established themselves as reliable and efficient components. As a dealer and distributor, NN Hydraulic India, based in Delhi, India, is proud to provide customers with high-quality Linde hydraulic pumps. In this article, we will explore the features, benefits, applications, and importance of Linde hydraulic pumps, helping you understand why they are a preferred choice for various industries.

What is a Linde Hydraulic Pump?

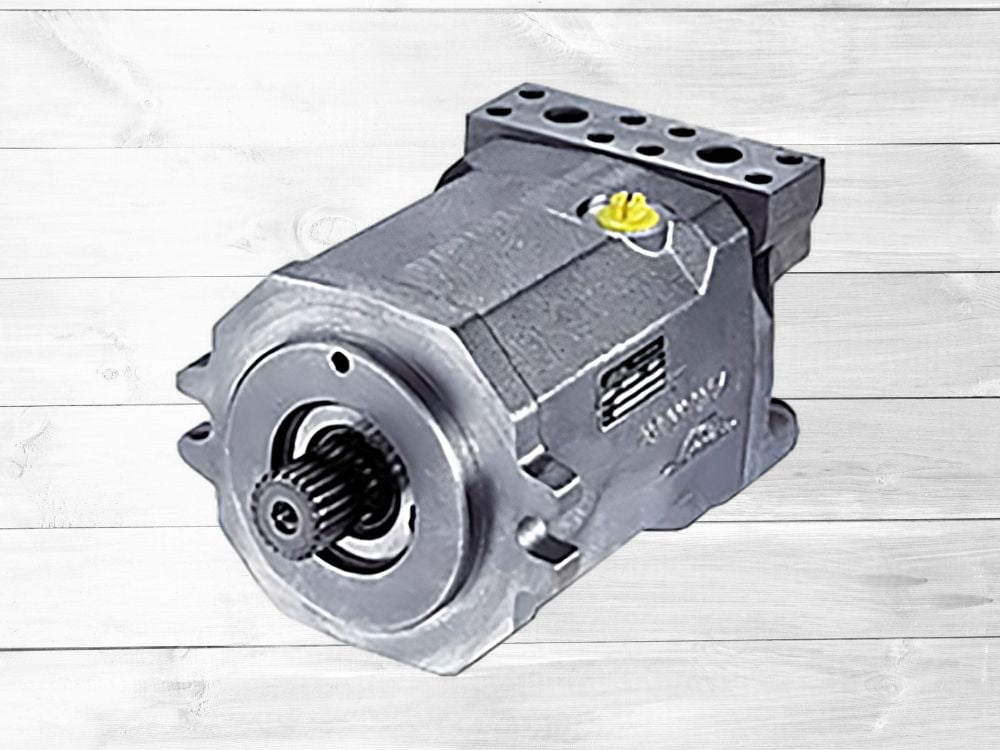

A Linde hydraulic pump is a mechanical device designed to convert mechanical power into hydraulic energy. It plays a crucial role in hydraulic systems by generating the necessary fluid flow and pressure required to power hydraulic machinery. These pumps are known for their precision, durability, and high performance, making them a popular choice in industrial applications.

Importance of a Hydraulic Pump

Hydraulic pumps are vital components in hydraulic systems, enabling the transfer of power from one location to another. They provide the force required to move hydraulic fluid, which in turn drives cylinders, motors, and other hydraulic machinery. Without a reliable hydraulic pump like the Linde hydraulic pump, hydraulic systems would not be able to perform their intended functions effectively.

Types of Linde Hydraulic Pumps

Linde offers a range of hydraulic pumps to cater to different application requirements. Let’s explore some of the commonly used types:

Axial Piston Pumps

Axial piston pumps are widely used in industrial applications. They operate by using pistons arranged in a circular pattern within a cylinder block. The pistons reciprocate in response to the rotating swashplate, creating the necessary fluid flow and pressure. Axial piston pumps are known for their efficiency, compact design, and precise control.

Radial Piston Pumps

Radial piston pumps are characterized by pistons arranged radially around a central cam or shaft. These pumps are known for their high-pressure capabilities and excellent volumetric efficiency. They are commonly used in applications that require high power density and reliable performance.

Vane Pumps

Vane pumps utilize a series of vanes mounted on a rotor to generate hydraulic flow. The vanes slide in and out of slots in the rotor, creating chambers that capture and discharge fluid. Vane pumps offer quiet operation, consistent performance, and are often used in mobile applications.

Features and Benefits of Linde Hydraulic Pumps

Linde hydraulic pumps come with a host of features and benefits that contribute to their widespread usage. Some notable advantages include:

High Efficiency: Linde hydraulic pumps are designed for optimum efficiency, minimizing energy loss and maximizing output.

Precision Control: These pumps offer precise control over fluid flow and pressure, allowing for accurate operation of hydraulic systems.

Durability: Linde hydraulic pumps are built to withstand demanding conditions, ensuring the longevity and reliability of the hydraulic system.

Compact Design: Linde hydraulic pumps are designed to be compact, saving space and making them suitable for various installations.

Versatility: These pumps can handle a wide range of hydraulic fluids, making them adaptable to different applications and environments.

Low Noise Levels: Linde hydraulic pumps are engineered to operate with reduced noise levels, minimizing disturbances in the working environment.

Easy Maintenance: With proper maintenance, Linde hydraulic pumps offer long service intervals and simplified maintenance procedures, reducing downtime and optimizing productivity.

Applications of Linde Hydraulic Pumps

Linde hydraulic pumps find applications across various industries and sectors. Some common applications include:

Construction Machinery: Linde hydraulic pumps are used in excavators, loaders, bulldozers, and other construction equipment, providing the necessary power for lifting, digging, and pushing operations.

Agricultural Machinery: Tractors, combine harvesters, and other agricultural machinery rely on Linde hydraulic pumps for powering hydraulic systems, such as steering, lifting implements, and operating attachments.

Material Handling Equipment: Forklifts, cranes, and other material handling equipment utilize Linde hydraulic pumps for smooth and precise movement of loads, enhancing operational efficiency.

Industrial Machinery: Linde hydraulic pumps are widely used in industrial machinery, including presses, machine tools, metalworking equipment, and more, enabling accurate control and reliable performance.

Choosing the Right Linde Hydraulic Pump

Selecting the appropriate Linde hydraulic pump for your specific application is crucial for optimal performance. Consider the following factors when choosing a pump:

Flow and Pressure Requirements: Determine the required flow rate and pressure range based on the hydraulic system’s demands.

Operating Environment: Consider factors such as temperature, humidity, and contamination levels to ensure the pump’s suitability for the operating conditions.

Application Specifics: Evaluate the specific needs of your application, such as speed control, load handling, and precision requirements, to select the most suitable pump model.

Compatibility: Ensure compatibility with other hydraulic components, such as valves, cylinders, and motors, to ensure seamless integration and efficient system operation.

Maintenance and Troubleshooting Tips

Proper maintenance is crucial to keep Linde hydraulic pumps in optimal condition. Here are some maintenance and troubleshooting tips:

Regular Inspections: Conduct routine inspections to identify any leaks, worn-out components, or signs of damage. Address any issues promptly to prevent further damage.

Fluid Quality: Monitor and maintain the hydraulic fluid’s cleanliness and viscosity within recommended specifications. Regularly replace the fluid and filters as per manufacturer guidelines.

Lubrication: Ensure adequate lubrication of the pump’s moving parts according to the manufacturer’s recommendations.

Seal Maintenance: Regularly inspect and replace seals if necessary to prevent leaks and ensure proper sealing.

Troubleshooting: In case of pump-related issues, refer to the manufacturer’s troubleshooting guide or seek professional assistance to diagnose and resolve the problem effectively.

Overall, Linde hydraulic pumps play a vital role in powering hydraulic systems across various industries. As a dealer and distributor, NN Hydraulic India offers high-quality Linde hydraulic pumps that provide efficient, reliable, and precise operation. Understanding the importance, types, features, applications, and maintenance of these pumps is essential for making informed decisions and maximizing the performance of hydraulic systems.

Explore More: Linde Hydraulic Pump Range

Hi, this is quite helpful information, I apricate that keep publishing this type of posts

Please take some time to visit mine, as we provide control cables for Linde Hydraulic Equipment and we can collaborate

Thank you for your comment, we will get back to you soon!

Hi, NN Hydraulic India, this is Himanshu, We are a reputed firms based in Delhi. We require Linde Hydraulic Solutions, I was searching on Google and found this blog post, Please share your details or contact us by visiting our website.

Sure, we will get back to you

A knowledgeful read that left me feeling genuinely happy! The writer’s knack for blog posting makes the information for Liebherr hydraulic even more impactful.